The Turbosupercharger and the Airplane Power Plant

General Electric

January, 1943

This pamphlet was published by General Electric, the builders of most U.S.

turbosuperchargers before and during World War II. This document was later published as

Technical Manual TM 1-404, dated 30 December, 1943. Translated to HTML format and

production Copyright © 1997 by Randy Wilson.

NOTE: To keep this document from loading too slowly, not all figures are

displayed. However, all figures are available to view by clicking on the linked Fig.

number. To return to this document, click on your browser's BACK button or arrow.

- General

- Rapid progress has been made in the last few years in the development and production of

military aircraft for effective high-altitude operation. High altitude precision bombing

and the advantage of full power at high altitude in combat have proved their value as

important elements of air supremacy.

- Airplane power plants of greater power output and reduced weight per unit of power

output are continually being produced.

- To understand thoroughly the important part played by the turbosupercharger in achieving

the above objectives, it is necessary to consider the source of power output of a gasoline

engine.

- Combustion

- The combustion, or burning, which occurs within a gasoline engine, is the source of

power which drives an aircraft. The carbon and hydrogen in the gasoline combine with the

oxygen in the air and the resultant vapor enters the engine. When such a chemical

combination takes place, the proportion by weight of the elements entering into the

combination is definitely fixed by chemical laws. As the composition of gasoline is very

uniformly 85 per cent carbon and 15 per cent hydrogen by weight, and air is 21 per cent

oxygen by weight, the weight of gasoline which will completely burn in a pound of air

without waste is definitely fixed. Fourteen and one-half pounds of air will support the

complete combustion of one pound of gasoline or, as more commonly expressed, 0.069 pounds

of gasoline per pound of air. It is necessary to have the right amounts of both fuel and

air in order to develop maximum power.

-

If less than this weight of gasoline is supplied to the engine for

each pound of air supplied, we say that he mixture is lean. In this case, the oxygen in

the excess air can find no carbon or hydrogen with which to combine and, therefore,

performs no useful work in the engine. The power generated by the engine is accordingly

reduced below normal, since the available space in the cylinders is not fully used in

burning the fuel from which the power is derived. Reducing the rate at which fuel is fed

to the engine may be regarded as a form of throttling. If less than this weight of gasoline is supplied to the engine for

each pound of air supplied, we say that he mixture is lean. In this case, the oxygen in

the excess air can find no carbon or hydrogen with which to combine and, therefore,

performs no useful work in the engine. The power generated by the engine is accordingly

reduced below normal, since the available space in the cylinders is not fully used in

burning the fuel from which the power is derived. Reducing the rate at which fuel is fed

to the engine may be regarded as a form of throttling.

- When more than 0.069 pounds of gasoline is supplied to an engine for each pound of air

supplied, we say the mixture is rich. Some carbon and hydrogen in the excess gasoline will

pass through the engine in a gaseous form without being burned. As these gases could be

burned to perform work if sufficient oxygen (air) were present, there is a resulting loss

of combustion efficiency, which means poor fuel economy.

The mixture condition, or pounds of fuel per pound of air supplied to an aircraft engine

is called the fuel-air ratio or F/A. Fig. 1

shows the range of fuel-air ratios used with an aircraft engine. Note that an airplane

engine is usually operated on the rich side of the chemically correct fuel-air ratio

(0.069), and that a very considerable excess of fuel is used for take-off and full

military power. This excess fuel serves to cool the engine, and the engine tends to run

more smoothly with less danger of backfiring into the intake manifold. There is also an

increase in power with richer mixtures.

- It is evident from the above discussion that the performance of a gasoline engine is as

dependent upon the weight of air it receives as it is upon the amount or fuel supplied to

it. It is the intent of this manual to discuss the problems, and the solutions to the

problems, of supplying the aircraft power plant with the combustion air it requires for

maximum performance.

- Supercharging

-

The conventional automobile engine is an unsupercharged engine.

In this type of engine, air fills the cylinder when the piston moves down. Power developed

depends on pounds of air in the cylinders. Supercharging, by in-creasing pressure, puts

more pounds of air in the same cylinder volume and, therefore, more power is developed.

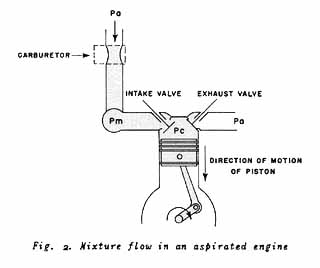

Referring to Fig. 2, the amount of

mixture charge which flows into the cylinder during the intake stroke depends upon the

difference between the pressure in the manifold (Pm) and the pressure in the cylinder

(Pc). There must be a pressure difference between these two points to offset the pressure

losses caused by the flow of the mixture through the intake valve and to overcome the

inertia of the gases in the manifold. The pressure in the manifold is always somewhat less

than atmospheric pressure (Pa) because of the resistance to flow set up by the carburetor.

If the pressure of the mixture in the manifold (Pm) is increased by mechanical means above

the manifold pressure round in the unsupercharged engine, more mixture charge will flow

into the cylinder, with resulting increase in horsepower. The process of mechanically

increasing the manifold pressure is called supercharging, and where this is done the

engine is a supercharged engine. The conventional automobile engine is an unsupercharged engine.

In this type of engine, air fills the cylinder when the piston moves down. Power developed

depends on pounds of air in the cylinders. Supercharging, by in-creasing pressure, puts

more pounds of air in the same cylinder volume and, therefore, more power is developed.

Referring to Fig. 2, the amount of

mixture charge which flows into the cylinder during the intake stroke depends upon the

difference between the pressure in the manifold (Pm) and the pressure in the cylinder

(Pc). There must be a pressure difference between these two points to offset the pressure

losses caused by the flow of the mixture through the intake valve and to overcome the

inertia of the gases in the manifold. The pressure in the manifold is always somewhat less

than atmospheric pressure (Pa) because of the resistance to flow set up by the carburetor.

If the pressure of the mixture in the manifold (Pm) is increased by mechanical means above

the manifold pressure round in the unsupercharged engine, more mixture charge will flow

into the cylinder, with resulting increase in horsepower. The process of mechanically

increasing the manifold pressure is called supercharging, and where this is done the

engine is a supercharged engine.

- The Effect of Altitude on Engine Performance

- The weight of the earth's atmosphere is sufficient to exert considerable pressure on

objects at sea level. At altitudes above sea level, the atmospheric pressure will be

lower. For example, the weight of air above the earth exerts a pressure or 14.7 pounds per

square inch on objects at sea level. The weight of air above 25,000 feet exerts a pressure

or only 5.45 pounds per square inch on objects at that altitude. Fig. 3 shows the variation of the

pressure of standard air with altitude.

- The density of air is the weight of a cubic root of air. Density of air depends upon its

pressure and temperature. (The effect of temperature on density will be discussed later.)

The greater the pressure of the air, the greater is the weight of a cubic foot of air. The

less the pressure, the less the air weight per cubic foot. At 25,000 feet, a cubic foot of

air weighs only 45 per cent as much as a cubic foot of air at sea level. It was stated

that the engine required an adequate weight of air, in order to develop its rate output.

As the altitude at which an aircraft is flown is increased, the air pressure becomes less,

and the density, or pounds of air per cubic foot, becomes less. If the engine is to

maintain its rated horsepower at increased altitudes, it must take a much larger volume of

air from the atmosphere surrounding it, in order to keep the weight flow from decreasing.

- Because of limitation of cylinder displacement, which is a measure of volume, the

unsupercharged engine cannot handle greater volume of air as altitude is increased.

Therefore, the horsepower output of such an engine decreases with altitude.

- By properly supercharging an engine, the weight of air flow to it can be maintained at

the point of rated power output. This is done by mechanically pumping air from the

atmosphere surrounding the aircraft into the engine manifold, at the pressure required, to

obtain the rated power output or the engine.

- While an aircraft can fly at altitudes where the output of its power plant is

appreciably less than its rated sea-level value, the speed, maneuverability, and rate of

climb or the plane decreases as the power drops off. The diagram in Fig. 4 gives a graphic comparison of the

performance of typical unsupercharged and supercharged aircraft with respect to altitude

of flight. In this diagram, it is assumed that the ceiling at which an airplane can be

flown with sufficient stability and maneuverability is the altitude at which the power

plant output is 30 per cent of its rated sea-level output. The height of the black columns

represents the power available to the propeller at the respective altitudes. The spacing

of the altitude lines is in proportion to the volume of air required by the engine to

produce 1 hp, as is indicated in the column to the left of the figure.

- Advantages of Full Power at Altitude

- The speed of an aircraft, which can maintain its rated power output, increases as the

altitude at which it is flown is increased. This is true because the air resistance, which

limits the speed of the airplane, decreases as the density of the air in which it is flown

decreases. The adjustable-pitch propeller maintains its thrust in the lighter density air

by taking a larger bite with each revolution. Fig.

5 shows how the speed of an airplane will be increased by flying at higher

altitudes, if the power output or the engine is maintained constant. This effect of

increased speed may be used on a military mission to reach the objective more quickly, or

may be used as an element of superiority over enemy aircraft which are not able to

maintain full power at the altitude or combat.

- By use of the turbosupercharger, it is usually possible to fly at the particular

altitude and speed which will result in maximum over-all efficiency. This means that less

fuel would be required for each mile travelled, and the range of the airplane would be

increased. In the case of a bomber, the savings in fuel requirements could be made up by

an increased bomb load.

- The ability to fly at high altitudes will permit the airplane to fly above much bad

weather which might otherwise have to be circled.

- Flying at high altitude greatly reduces the hazard of antiaircraft fire and the

possibility or effective attack by interceptor planes. This factor is of particular

importance for the period of flight before the plane reaches its objective.

- Methods of Supercharging

- A supercharging system suitable for full-engine-power operation at high altitude must be

able to take in air at high-altitude density and pressure, compress it, and deliver it to

the engine intake manifold at the required pressure (and, therefore, at the right

density). Either a pump or a blower may be designed to do this. When the proper condition

of pressure is created in the intake manifold, the weight flow of the mixture into the

engine cylinder will be adequate.

- The engine manifold pressure, being a measure of the weight flow of the fuel-air mixture

to the engine cylinders, is also a measure of the power output of the engine running at a

constant speed. Fig. 6 shows the

relative effect of manifold pressure on the power output of an engine. From this figure it

is evident that increasing the manifold pressure (supercharging) is a most effective way

of greatly increasing the horsepower output of an engine without increasing its size and

weight.

- It is very important to note that, during warm-up or flight operation, the maximum

manifold pressure specified by the engine manufacturer must not be exceeded. Excessive

manifold pressure will force so great a weight charge of mixture into the engine that the

power output, internal heat, and mechanical stress within the engine will be greater than

that for which the engine was designed. This overstressing of the engine would greatly

reduce its life of operation and might result in immediate engine failure. This is a

frequent cause for burning up cylinders and blowing off cylinder heads.

- Operation recommendations provide for use of high manifold pressure and maximum power

for short periods of time. This "military" or "take-off.' power is used

when high power is required for take-off or to meet a military emergency in combat.

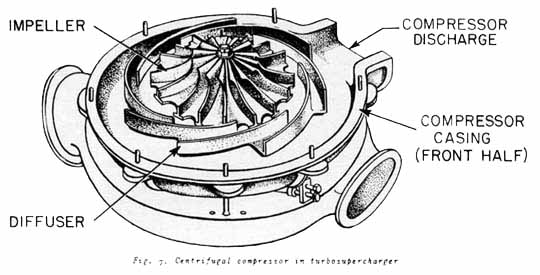

- The characteristics of the centrifugal compressor make it the most effective type for

aircraft-engine supercharging. This type of compressor operates most effectively at high

speeds, and has the ability to compress a large volume of air at low pressure. Because the

centrifugal compressor runs at high speeds, its size is relatively small and its weight is

light. It also has minimum moving parts, and the problems of lubrication and maintenance

are thereby minimized. The centrifugal compressor consists of three basic elements -- the

impeller, the diffuser, and the casing. Air enters the impeller at the center and is

discharged radially at the ends of the blades with high velocity energy. The diffuser

converts this energy to pressure energy. The casing collects the air under pressure for

delivery to the engine induction system. Fig. 7

shows a centrifugal compressor with half of the casing removed to expose the impeller and

diffuser.

- Superchargers

- Internal Superchargers

- A supercharger which is located between the carburetor outlet and the intake manifold of

the engine is called an internal supercharger. A supercharger thus located serves to

provide a uniform distribution of the fuel-air charge to the various cylinders, as well as

to increase the density of the charge. Maintaining a high manifold pressure ahead of the

intake valves allows the use of "valve overlap" in the engine, so that the

intake valve opens just before the exhaust valve closes at the end of the exhaust stroke.

This allows the compressed mixture from the intake manifold to scavenge the spent gases

out of the clearance volume of the cylinder and also tends to improve the cooling of the

exhaust valve. This cooling is of particular importance when operating at

"military" or "take-off" power. With no supercharging between the

carburetor and the intake valves, "valve overlapping" would permit exhaust gases

to flow back into the intake manifold. This would cause backfiring and dilution of the

next charge of mixture with burned exhaust gases.

- An internal supercharger is always used to obtain maximum performance from modern

high-power aircraft engines and high-grade fuels. The internal supercharger is built into

the airplane engine and is called a geared supercharger.

- The power required to drive the geared supercharger is taken, through a train of gears,

from the engine crankshaft. Thus, the net power output available to drive the propeller is

decreased by the amount which is taken from the crankshaft to drive the geared

supercharger.

- External Superchargers

- A supercharger located ahead of the carburetor in the induction system is called an

external supercharger. An external supercharger is used primarily to obtain full-power

engine performance at high altitudes, and is generally driven by an exhaust-gas turbine. A

supercharger so driven is called a turbosupercharger. In a turbosupercharged power plant,

the high-altitude air is compressed to approximately sea-level pressure before delivery to

the engine carburetor. The temperature of the air passing through the compressor of the

turbosupercharger is considerably increased as the result of the compression. This effect

of temperature increase is similar to the increase in the temperature of the barrel of a

tire pump during use.

- If the temperature of the air entering the engine exceeds certain limits, detonation

(knocking) will occur in the engine. This detonation would cause a sharp decrease in the

power output of the engine, and would greatly overstress parts of the engine. The

temperature limit of the carburetor-inlet air at which detonation in the engine will occur

depends upon the design of the particular engine and the temperature rise in its internal

supercharger.

- Also, the density (weight per cubic foot) of the air charge again enters the picture. As

the temperature of the entering air is increased, its density becomes less. To offset the

temperature rise due to compression, an intercooler is installed between the

turbosupercharger air discharge and the carburetor inlet.

- This intercooler is similar in its operation to the conventional automobile radiator,

except that the transfer of heat is from the compressed air to the cooling air instead of

from water to the cooling air. The cooling air is taken from a "ramming" air

intake on the aircraft and is fed by means of ducts through one series of passages in the

intercooler. Hot air from the turbosupercharger is fed through another series of passages,

running in a cross-direction to the cooling air. These two paths of air flow are separated

by thin metal walls, and the heat transfer takes place through these walls.

- Cooling air leaving the intercooler is normally ducted to a discharge opening in the

aircraft structure. Shutters or doors are located in the cooling-air circuit so that the

pilot can control the temperature of the air entering the carburetor by varying the amount

of cooling air used in the intercooler. In practice, the intercooler is so designed that

the maximum temperature of the air which enters the carburetor will not exceed a

relatively high sea- level temperature (90 F to 100 F).

- The engine exhaust is connected directly to the nozzle box of the turbosupercharger with

a gastight stack. In order that the energy in the hot exhaust gases may be used to furnish

the power which is used by the turbine to drive the turbosupercharger, it is necessary to

build up the pressure in the exhaust stack and nozzle box sufficiently, so that the gases

will acquire a high velocity when expanding through the nozzles of the turbine down to the

pressure of the atmosphere in which the airplane is flying. Tests have shown that the

pressure built up in the exhaust stack by the turbine is almost the same as the pressure

built up in the carburetor by the compressor, and is normally about sea-level pressure,

regardless of altitude at which the airplane is flying. Thus, under normal conditions of

operation, the engine would receive its charge at sea-level density and would exhaust at

sea-level pressure. Therefore, the engine will develop sea-level horsepower up to the

rated altitude of the installation. In brief, the turbo-supercharger supplies an

artificial sea-level atmosphere to the engine.

- The turbosupercharger may be used to increase rated engine power at sea level, or to

furnish "ground boost", as well as to maintain rated power at high altitude.

Although the turbosupercharger speed required for this purpose is much less than the rated

speed, it is necessary to build up the engine exhaust pressure appreciably above the

atmospheric pressure at sea level, and other low altitudes, in order to furnish turbine

power. The amount by which this exhaust pressure can be increased without unduly affecting

engine operation will depend upon the particular engine in question. It is very important

that the instructions covering the specific aircraft involved be closely followed in the

operation of a turbosupercharged power plant.

- Turbosuperchargers

- At the present time, turbosuperchargers are used in series with geared superchargers,

the intercooler and carburetor being located between them. In this way, maximum use can be

made of the advantages of each type.

- A geared supercharger has one obvious advantages of compactness, lightness, and ease of

installation. The greatest disadvantage of the geared supercharger is its application for

high-altitude flight is its inflexibility of speed. If it is designed to develop sea-level

pressure at 20,000 feet, for example, it will deliver an excessively high pressure at sea

level with the carburetor throttle opened wide, so that the throttle must always be

partially closed for low-altitude operation. However, since the speed is not reduced, the

supercharger drive still subtracts from the power available to the propeller, an amount

approximately equal to the power taken at rated altitude. In an effort to reduce these

difficulties, two-speed and two-stage geared superchargers have been designed and built.

These are better than the single-speed, single-stage machine, but they necessitate an

increase of size, weight, and complexity. No matter how many stages or different gear

ratios are used, such a geared supercharger can never have the perfect flexibility of

speed control of a turbosupercharger, and must always involve some waste of power when

operating below the altitude for which it was designed. The speed of the turbosupercharger

can be controlled to maintain desired conditions of carburetor-inlet pressure without

regard to the engine speed.

- Operating Characteristics

-

The operating characteristics of engines equipped with various

types of superchargers is shown on the general altitude-vs-engine-horsepower diagram of Fig. 8. The line (A) indicates the

variation in horsepower of an engine built without an internal supercharger or a

turbosupercharger. As illustrated, the power begins to fall off as soon as altitude is

increased. The plane can fly to considerable altitudes, but the power is so reduced that

finally a point will be reached where there is insufficient power to maintain the plane in

level flight. The operating characteristics of engines equipped with various

types of superchargers is shown on the general altitude-vs-engine-horsepower diagram of Fig. 8. The line (A) indicates the

variation in horsepower of an engine built without an internal supercharger or a

turbosupercharger. As illustrated, the power begins to fall off as soon as altitude is

increased. The plane can fly to considerable altitudes, but the power is so reduced that

finally a point will be reached where there is insufficient power to maintain the plane in

level flight.

- Line (B) shows the approximate characteristics of an engine equipped with a single-stage

geared supercharger. In this case, there is some reduction in power at sea level because

some of the engine power is required to drive the supercharger and, hence, is not

available to the propeller. This deficiency in power over that of an unsupercharged engine

is overcome very shortly as altitude is increased, and nearly constant power continues to

the critical altitude of the geared supercharged engine, which is in the order of 6000

feet to 7000 feet. Beyond this altitude power diminishes as altitude is increased, but the

altitude at which the plane will continue in level flight is greater than that of an

unsupercharged engine.

- Line (c) shows the characteristic of a two-stage geared supercharger and, here again,

the altitude at which engine power begins to fall off has been advanced, because of the

higher pressure ratio obtainable when two stages of compression are employed. Somewhat the

same effect can be obtained by single-stage, two-speed super chargers. In either of these

combinations, however, the critical altitude where the power begins to diminish is at

about 18,000 feet.

- Line (D) indicates the characteristic of a plane equipped with single-stage

internal-supercharged engines and turbosuperchargers. The power available to the propeller

is still the same as obtained from a single-stage supercharged engine, and this power

continues to an altitude of approximately 25,000 feet. Beyond the critical altitude, there

is sufficient power to maintain flight to altitudes of at least 35,000 feet.

- The Turbosupercharged Power Plant

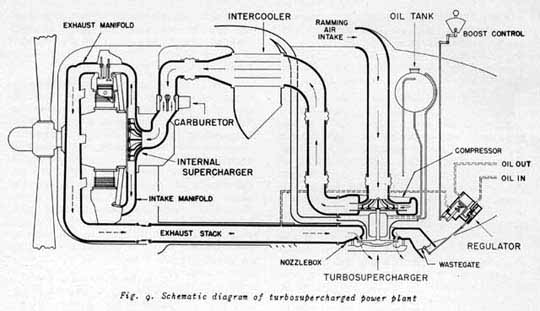

- It is well to consider the turbosupercharged power plant with reference to the part

played by each of the elements which go to make up a turbosupercharger system. Fig. 9 is a schematic diagram of a

complete turbosupercharger system.

- Air, which will eventually be supplied to the engine to support combustion, is taken

into the system through what is called a "ramming" air intake. This intake is

usually located on the leading edge of the engine nacelle or wing, and is designed to take

full advantage of the velocity of the plane through the air or the force of the air

velocity of the propeller wash, to obtain what is, in effect, a small amount of

supercharging in the intake itself. This air is directed to the inlet of the compressor of

the turbosupercharger where the first compression of the air is made. The amount of the

compression depends upon the speed at which the turbosupercharger is operated, and the

compression ratio may be as high as 2.86 to 1. This means that atmosphere taken into the

compressor at an altitude of 25,000 feet with apressure of approximately 11 inches of

mercury, may be discharged from the compressor with a pressure of approximately 50 inches

of mercury. As a result of this compression, the temperature of the air leaving the

compressor would be sufficiently high to cause detonation, if fed directly to the

carburetor. For example, if the entering air is -30 F at an altitude of 25,000 feet, the

temperature of the air leaving the compressor would be approximately 150 F. To reduce this

temperature, the air is passed through the intercooler before going to the carburetor. As

mentioned before, this cooling also serves to increase the density of the air charge. The

mixture of the air and fuel takes place at the inlet to the geared supercharger. The

temperature of the mixture leaving the carburetor is somewhat less than the entering air

temperature, because of the removal from the air of the heat requiredd to vaporize the

fuel.

- The mixture charge from the carburetor is then fed to the inlet of the gear-driven

internal supercharger. In this second stage of compression, a compression ratio of

approximately 1.5 to 1 at rated engine speeds is normally used. With the moderately low

compression ratio of this stage, the temperature rise of the mixture is not excessive, but

sufficient pressure is maintained to assure uniform distribution of the mixture to the

cylinders and to allow the use of "valve overlap" for exhaust-gas scavenging and

exhaust-valve cooling.

- Hot exhaust gases from the cylinders are collected in manifold or collector ring through

the exhaust stack to the nozzle box of the turbosupercharger. The nozzles are designed to

allow the gases to expand, and, thereby, to reach high velocities before striking the

buckets of the turbine wheel. Exhaust gases which are not required to drive the turbine

are by-passed through a waste gate to atmosphere before reaching the turbine nozzles. This

completes the cycle of the air required by the engine or combustion as it is passed

through a turbo-supercharged power plant.

Fig. 10 shows pressures and

temperatures encountered in a typical turbosupercharger application operating at 25,000

feet.

- Description of Turbosupercharger

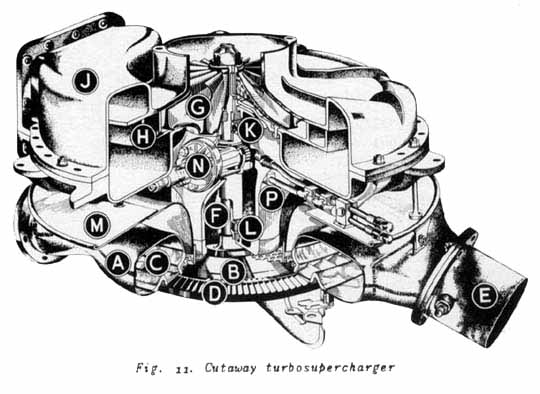

- Fig. 11 shows a cutaway view of a

typical turbosupercharger. This is simply a high-speed centrifugal compressor driven by a

turbine which derives its power from the hot exhaust gases of the engine. The exhaust

stack connects to the nozzle box (A), which is directly above the turbine wheel (B). The

hot gases escape from the nozzle box through fixed nozzles (C). The nozzles permit an

expansion of the exhaust gases which increases velocity and directs it against the buckets

(D) on the turbine wheel. The high speed and power of the turbine are the results of the

flow of these high-velocity gases against the turbine buckets. The speed of the

turbosupercharger is controlled by allowing excess gases, not required for turbine

operation, to escape through the waste gate (B), instead of through the turbine nozzles

and turbine wheel. With the waste gate closed, all the gases will go through the turbine,

and it will revolve with maximum speed and power. With the waste gate wide open, the

turbine will idle.

- The power developed is transmitted through the shaft (F) to the impeller (G) of the

centrifugal compressor, which is mounted on the opposite end of the shaft. Engine air is

ducted from a ramming air intake on the leading edge of the wing or front of the nacelle

to the inlet of the compressor. The impeller (O) and diffuser (H) are enclosed in a

suitable housing called the compressor casing (J), which collects the compressed air from

the diffuser. The rotating assembly is supported by ball and roller bearings which carry

the thrust and static loads imposed. The ball bearing (K) is located on the impeller end

of the shaft, and takes the thrust load of the shaft, which is in the direction of the

impeller when the turbosupercharger is running. The roller bearing (L) allows for

expansion of the shaft.

- The baffle ring (M) assures the proper distribution of the turbosupercharger cooling air

between the nozzle box and the compressor casing. The baffle ring also serves as a shield

to prevent the transfer of heat from the nozzle box to the compressor casing by radiation.

- The turbosupercharger is lubricated by a built-in oil pump (N), which is driven by a

worm gear from a worm sleeve keyed to the shaft. The pump and bearings are enclosed by the

bearing-and-pump casing (P). The turbine wheel is cooled by a cooling cap. The standard

type of cooling cap is of the convection type, and directs cooling air from the aircraft

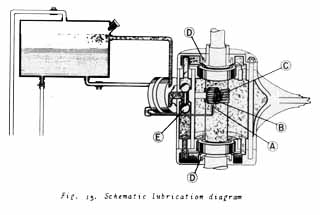

slipstream against the turbine wheel. Fig. 12,

13, and 14 show the completed turbosupercharger

assembly.

- Lubrication of Turbosuperchargers

- Lubrication pump

- The turbosupercharger lubrication pump is really two separate positive-displacement

pumps on the same shaft. One of the elements of the pump supplies oil to the gears and

bearings. The other element is a scavenging pump which removes oil from the housing and

returns it to the supply tank.

- There is a tachometer connection on the end of the pump shaft, from which the speed of

the turbosupercharger can be determined.

-

Fig. 15 is

a schematic diagram of a turbosupercharger lubrication system, using a separate oil tank.

The oil for lubricating the turbosupercharger from the oil pump enters the inside of the

bearing and pump housing through a shroud (A) which lubricates the pump drive gear (B).

The oil is transferred from the shroud by the drive gear to the mesh of the drive gear and

the worm thread sleeve (C). The bearings are oiled by the splash from the drive gear, and

by the oil mist which exists inside of the bearing housing as a result of the high

rotation speeds and churning of the oil. This combination of splashing and oil mist is

ideal lubrication for the ball and roller bearings. Some turbosuperchargers are designed

with jets which deliver oil directly on the ball and roller bearings. This provides no

better lubrication than the oil mist, but it does provide for more efficient cooling of

the bearing. Fig. 15 is

a schematic diagram of a turbosupercharger lubrication system, using a separate oil tank.

The oil for lubricating the turbosupercharger from the oil pump enters the inside of the

bearing and pump housing through a shroud (A) which lubricates the pump drive gear (B).

The oil is transferred from the shroud by the drive gear to the mesh of the drive gear and

the worm thread sleeve (C). The bearings are oiled by the splash from the drive gear, and

by the oil mist which exists inside of the bearing housing as a result of the high

rotation speeds and churning of the oil. This combination of splashing and oil mist is

ideal lubrication for the ball and roller bearings. Some turbosuperchargers are designed

with jets which deliver oil directly on the ball and roller bearings. This provides no

better lubrication than the oil mist, but it does provide for more efficient cooling of

the bearing.

- The capacity of the scavenging element of the pump is about three times that of the

pressure pump at all times. Because of this, two thirds of the scavenging-pump delivery is

air. The pumping of this air causes a slight vacuum in the bearing housing, which is

necessary to prevent oil leakage through the shaft oil seals. The two shaft oil seals (D),

one on the turbine end and the other on the compressor end of the bearing housing, are not

rubbing seals, but have a clearance from the shaft of 0.002 in. to 0.005 inches. These

seals are threaded to cause an inward flow, which tends to keep the oil inside the pump

and bearing casing. This action is assisted by the vacuum which is created inside the

casing by the excess capacity of the scavenging pump.

- The dumbbell valve (E) operates by gravity. The intake of the scavenging pump is through

this valve, and the valve position will always be such that the scavenging-pump intake

will draw only from the bottom of the bearing and pump housing, regardless of the position

of the plane in flight.

- Turbosuperchargers are usually installed with a separate oil-supply tank of about one to

two gallons capacity, which is normally about 75 per cent full of oil. The excess volume

of the tank is necessary to accommodate any foaming of the oil which may be induced by the

scavenging pump.

- The rotor of the turbosupercharger operates at extremely high speeds compared with

speeds normally encountered in other equipment -- 21,300 rpm for a rated altitude of

25,000 feet for one type. At this speed, the balls in the ball bearing, for example, are

rotating at approximately 60,000 rpm about their own axis. Bearings which will stand up

under these extreme conditions of speed are of special design, and are manufactured with

extra-fine precision. It is obvious that special care must be used in the handling and

fitting of these bearings during overhaul operations. It is also of utmost importance that

no foreign matter be allowed to get into the lubricating-oil system, and that

recommendations on the oil used and the method of operation of the turbosupercharger be

closely followed.

- Turbosupercharger Coo1ing Requirements

- Fig. 16 shows a schematic diagram

of the various paths of cooling-air flow required in a normal turbosupercharger

installation. Cooling air is required for the exhaust-stack shroud, the turbine-wheel

cooling cap, the back of the turbine nozzle box, the compressor casing, the bearings, and

the intercooler.

- The exhaust stack is that part of the exhaust system which conducts the exhaust gas from

the engine collector ring or exhaust manifold to the turbine nozzle box. In the exhaust

stack are one or more flexible joints to allow for thermal expansion and engine vibration.

The usual design of the exhaust stack includes a ventilated shroud which is a concentric

pipe surrounding the exhaust stack, and which is ventilated by a rammed-cooling-air blast.

This exhaust-stack shroud serves the dual purpose of forming a fire wall around the

high-pressure exhaust stack, and providing a means for precooling the exhaust gases before

entering the turbine nozzle box.

- The convection-type cooling cap delivers cooling air to the rim of the turbine wheel at

the point of attachment of the turbine buckets to the wheel blank. The air is discharged

on the trailing edge of the wheel, to avoid recirculation of the air over the wheel.

- The bearings, compressor casing, and back of the nozzle box are cooled by a duct which

delivers air radially inward toward the center of the turbosupercharger. This air stream

is divided by the baffle ring, with approximately 40 per cent of the air passing between

the baffle ring and nozzle box, and the remainder between the baffle ring and compressor

casing.

- The volume of intercooler cooling air required is normally about double the amount of

the engine air which is cooled. Flaps or shutters, located downstream from the intercooler

in the cooling-air stream, provide a control of the air temperature entering the

carburetor.

- The turbosupercharger cooling air is taken aboard where full use can be made of the

propeller slipstream, or of the velocity of the plane, to assure adequate air supply and

distribution. Care is taken in locating the cooling-air ducts, so that minimum heat will

be picked up before the air reaches the turbosupercharger or intercooler. In particular,

the cooling-duct intakes are located so that no hot exhaust gas or discharged

engine-cooling air will be rammed into the cooling passages.

- Turbosupercharger Regulation

- One of the advantages of the turbosupercharger is flexibility of control. The speed of

the turbosupercharger rotor and, consequently, the pressure supplied to the engine, is

controlled by changing the amount of exhaust gases that pass through the nozzles to drive

the turbine wheel. Opening the waste gate allows more exhaust gases to be bypassed, and

the rotor speed is decreased.

Conversely, closing the waste gate will increase the rotor speed.

- A hydraulic regulator automatically moves the waste gate to hold the nozzle-box pressure

constant at the value determined by the position of the boost-control lever in the

cockpit. By changing the setting of the regulator, the proper exhaust pressure and

corresponding manifold pressure can be obtained for the desired engine power, such as

cruising, normal or military power.

- Fig. 17 is a diagram of a typical

hydraulic regulator. There is a tube leading from the nozzle box to the top bellows. The

bottom bellows is evacuated and serves to prevent the top bellows from acting in response

to atmospheric changes in pressure. Inside the top bellows is mounted a spring, one end of

which is connected to the junction between the two bellows, and the other end to the

range-shifting control lever. This lever is connected by linkages to the cockpit boost

control. The purpose of the spring and control-lever assembly is to allow the pilot to

vary the pressure on the spring for different nozzle-box pressure, corresponding to

different engine powers. This spring tension just balances the pressure in the top bellows

to the point where the servo-valve ports to the servo piston are closed.

- As pressure changes occur in the top bellows, they act on the servo valve and shift its

position, thereby opening ports which direct oil under pressure into one side of the

piston. The piston then moves under the unbalanced oil pressure, and moves the waste gate

with it. The servo piston continues to move the waste gate until the pressure in the

nozzle box has been corrected. When corrected, the pressure in the bellows restores the

servo valve to its closed-port position, and stops the piston motion.

- The regulating process, described above, occurs in a very short space of time, a few

seconds at most. Therefore, in actual operation, as soon as the exhaust pressure starts to

change, the hydraulic regulator starts to move the waste gatem a direction to counteract

this change. That is, for a given setting of the cockpit boost lever, the regulator always

acts to maintain a constant exhaust pressure, and the actual exhaust pressure varies from

this constant value only temporarily during those few seconds required by the hydraulic

regulator to move the waste gate in a direction which restores the pressure.

- For some pursuit airplanes equipped with turbosuperchargers, the size of the evacuated

bellows in the regulator is reduced. This causes the atmospheric pressure to have some

effect on the upper bellows and results in a slightly decreasing nozzle-box pressure with

increasing altitude. This type of regulator holds an approximately constant manifold

pressure without changing the setting of the boost control lever up to the airplane's

rated altitude.

- Installation Considerations

- Induction System

- The design and construction of the induction system is of primary importance in the

application of a turbosupercharger system. The induction system carries the required

engine air from the slipstream to and through the compressor element of the

turbosupercharger, then through the intercooler to the engine carburetor.

- Mention has been made of the use of rammed-air intakes. These intakes are specifically

designed to take the required weight flow of air on board the airplane with the least

disturbance of the slipstream over the air foil section. The "rammed-air

intakes" are preferably located on the leading edge of the wing or engine cowl. When

air scoops, which project from the surface of the aircraft are used, the trailing surface

of the scoop is appropriately streamlined so that minimum drag is introduced. Because of

the forward motion of the plane, the "rammed-air intakes" tend to increase the

pressure at the inlet to the compressor. This gain in pressure achieved by the

ramming-engine-air intake, is particularly important in the turbosupercharged power plant,

because this gain is multiplied by the compression ratios of the two stages of compression

which follow.

- The duct from the ramming-air intake usually consists of two or more sections of pipe

connected by flexible joints. These flexible joints are installed between the compressor

and the ramming-air intake to isolate vibration of the ship structure from the high-speed

turbosupercharger compressor. These flexible connectors are also incorporated between the

turbosupercharger compressor and the intercooler, and between the intercooler and the

carburetor-air intake. In the case of the connecting duct to the carburetor inlet, the

motion of the engine in its dynamic mounting must also be isolated by the flexible

connectors. Such flexible connectors usually consist of a neoprene or synthetic-rubber

sleeve which is band-clamped to the abutting end of the duct section.

- Another factor in the design of the induction system is to minimize the pressure losses

resulting from sharp bends, rapid changes in cross section, and use of undersize ducts.

Usually the airplane design dictates the path of the induction system. The best use must

be made of the space available to keep the induction-system losses low.

- Since the internal pressure of the induction system at high altitudes is as much as 10

to 11 pounds per sq in. greater than the external atmospheric pressure, the design

requires that the induction system withstand a pressure differential of 20 pounds per sq

in., without leakage. Any leakage which develops in the system represents a loss, and

detracts from the efficiency of the installation.

- The installation of an inter-cooler of the proper size and design is important in

maintaining the efficiency of the turbosupercharged power plant. The intercooler should

provide adequate cooling of the air discharged from the compressor, to assure the proper

charge density. At the same time, the inter-cooler should not be of excessive weight, and

should not offer too great a resistance to the engine air flow in the induction system.

- The exhaust system of the turbo-supercharged power plant carries the exhaust gas from

the cylinders to the nozzle box of the turbosupercharger. This piping must also contain

flexible joints to isolate vibration, and also to allow for expansion caused by heat. It

is very important that the exhaust piping shall exert no stresses on the nozzle box. If

stresses are allowed, the nozzle box will be distorted. During high-altitude operation,

the pressure inside the exhaust manifold may be 10 to 11 pounds per sq in. greater than

the atmospheric pressure. Again care must be taken to prevent leakage. Leaks in the

exhaust system will always tend to enlarge because of the high temperatures of the exhaust

gases. In normal installations, the exhaust stack is encircled by an exhaust cooling

shroud. Cooling air is forced through this annular passage. Gases leaking from the exhaust

pipe will leak into this space, and not into the plane structure. Leakage of the exhaust

gases will detract from the power available to drive the turbosupercharger, and will

thereby reduce the critical altitude of the installation.

- Fig. 18, 19, 20,

21, and 22 are schematic diagrams of typical

turbosupercharger applications.

- Care and Maintenance of Turbosuperchargers

- Turbosupercharger installations require very careful inspection and maintenance in

service. The turbosupercharger, although very simple in construction, operates at very

high speeds. Very great differences in temperature are prevalent in a relatively small

piece of equipment.

The effective operation of the turbosupercharged power plant depends upon the efficient

operation of all its component parts.

- Specific instructions for inspection and maintenance are covered by Technical Orders

covering this type of equipment. A brief summary of the items which require daily

inspection follows:

- Check the turbosupercharger, exhaust system, induction system, intercooler, and control

system for security of mounting and evidence of failure.

- Inspect the turbine buckets for distortion or other evidences of failure.

- Check clearance between turbine wheel and nozzles.

- Inspect and lubricate the waste gate.

- Check the oil supply for correct amount, and inspect the lubrication system for leaks.

- Immediately, at beginning engine run-up, determine that the turbine wheel is rotating

freely. Check operation of the regulator to determine if sluggish.

- Turbosupercharger overhaul, as well as any other repairs involving disassembly of the

unit, should be made only at air depots. To avoid damage to the unit, the instructions

covering the removal of the turbosupercharger from the airplane should be carefully

followed.

- Bearing replacement is recommended procedure on each normal overhaul.

- The supercharger parts having been reconditioned, the complete rotor assembly, Fig. 23, must be dynamically balanced,

in accordance with the detailed instructions of the Army Air Forces Technical Orders

covering this subject. Fig. 24 shows

the balancing machine used for this purpose. Balance of the impeller end of the rotor is

obtained by removing material at the scallops of the impeller. The turbine-wheel end of

the rotor is balanced by removing material (by grinding) from the inner face of the

turbine wheel.

The nozzle box is made of corrosion resistant steel, and repairs involving welding are

made with a type of welding electrode approved by the manufacturer. This electrode is

coated, so that the resulting weld has practically the same properties as the welded

material.

- Operation

- A turbosupercharger aircraft must be operated in strict accordance with the specific

instruction provided in the Army Air Forces Technical Order for operation of each type of

airplane. Operation may be discussed in a general manner by considering the

characteristics of the turbosupercharger and the effect of the turbosupercharger on the

aircraft power plant under different conditions of flight operation.

- Starting

The engine should be warmed up in the usual manner. The turbosupercharger regulator should

be in the OFF position so that the waste gate is in the open position. Particular care

must be taken to avoid any backfiring which may distort the waste gate or balloon the

nozzle box.

- Take-off

After warm-up of the engine, set the propeller at the rpm specified for take-off, then

open the throttle wide and bring up to the desired manifold pressure as quickly as

possible by use of the supercharger regulator control. Lock the regulator control and

close the throttle after the turbosupercharger has had sufficient time to reach the proper

speed, and the manifold pressure becomes stabilized. This procedure should be followed for

each engine in the case of multiengine airplanes. The airplane may then be taxied out for

takeoff, and when all the throttles are opened wide, the turbosupercharger regulator will

advance the manifold pressure to the predetermined value.

- Climbing

After take-off, the regulator should be adjusted to hold the pressure specified for climb,

which will usually be less than required for take-off. If the regulator is actuated by the

exhaust pressure at the nozzle box, as is customary at present, and the setting is kept

constant, the waste gate will gradually close as the airplane ascends, and the nozzle-box

pressure will remain approximately constant. Under such conditions, the intake-manifold

pressure will increase with altitude, and it will be necessary for the pilot to reset the

regulator at intervals to prevent this pressure from becoming too high. The engine should

never be supercharged more than the specified manifold pressure recommended for each

particular installation. Serious damage to the engine is certain to result if excessive

supercharging is continued.

- Cruising

When necessary to reduce engine power considerably below full power, such as for cruising,

the manifold pressure should be reduced with the supercharger control. It is not good

practice to obtain reduced power by maintaining a high carburetor-inlet pressure and

partially closing the carburetor throttle, since this produces an unnecessarily high back

pressure against which the engine must exhaust. This is not only harmful to the engine,

but also tends to develop excessive operating speeds of the supercharger rotor. It is

sometimes found advantageous to keep a high carburetor-inlet pressure and reduce the

engine speed by changing the propeller setting.

- Descent

In descending from high altitudes, sufficient power should be used to keep the engine

warm. It will be noticed that the response to sudden opening of the throttle in

turbosupercharged engines appears to be slow. This fact must be kept in mind when

maneuvering close to the ground and when landing.

- In some types of pursuit airplanes, the turbosupercharger boost control and the throttle

are interlocked, so that they can be operated by a single lever. In this case, the actual

operation of the turbosupercharged power plant must be constantly kept in mind.

Turbosupercharger regulators are now in use, which automatically reduce the exhaust

pressure of the system, as the altitude at which the airplane is flown is increased. This

results in maintaining an essentially constant manifold pressure of the engine to the

rated altitude of the airplane. This type of regulator reduces the amount of

turbosupercharger boost adjusting which the pilot must do during climb to rated altitude.

- High altitudes

- At high altitudes, in addition to the effect of low atmospheric pressures, the effects

of the low temperatures encountered are of great importance. The turbosupercharger must

always be operated at sufficient speed to insure that the oil in its lubrication system

will not congeal because of the low temperatures encountered. If the oil is allowed to

congeal, the interruption of the lubrication will cause serious damage to the bearings and

pump drive. In particular, high-altitude cruising or prolonged gliding should never be

done with the boost control in the OFF position.

- Carburetor de-icing may be effected with the turbosupercharger power plant by reducing

or cutting off the cooling air to the intercooler. This will cause high-temperature air

from the compressor of the turbosupercharger to supply the carburetor.

- It is particularly important that the manifold pressure of the engine be reduced as the

airplane climbs above its rated altitude. If this is not done, the turbosupercharger will

be seriously overspeeded while supplying air in excess of its rated design.

- Flight test work on airplanes equipped with turbosuperchargers and automatic-pilot

control has indicated that extreme caution should be taken. Supercharged airplanes will

fly at altitudes far above those at which the human body can survive without the aid of

special equipment.

Even with an abundance of oxygen, crew members should preferably be so located that no

person is entirely alone in any one compartment. Furthermore, it is dangerous to move from

one compartment to another without oxygen.

Pilots, especially, should be cautious in the use of the automatic pilot at high

altitudes, both from the control standpoint and the possibility of gradually falling

asleep as the oxygen supply is diminished. In this case, the airplane will continue to fly

on the automatic pilot until the gas supply is exhausted.

- Care in Operation and Maintenance

The turbosupercharger has proved very reliable in operation under all conditions of

high-altitude combat flying. It requires the same care in operation and maintenance that

is required by any piece of high-precision equipment. Occasionally, in situations of great

emergency, the turbosupercharger is called upon to perform far in excess of its design

rating. The ability of the turbosupercharger to so perform, and its ultimate life under

such conditions, depend largely on the care which was exercised in its previous operation

and maintenance.

|